Robotic Arc Welding Fixtures

What is a Robotic Arc Welding Fixture? What are Key Quality Characteristics of a Robust, Well-Built Robotic Arc Welding Fixtures?

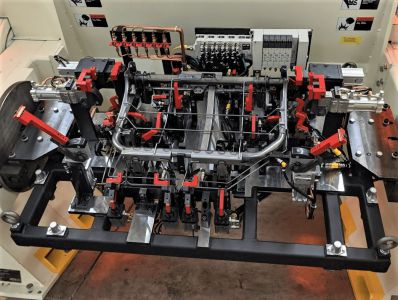

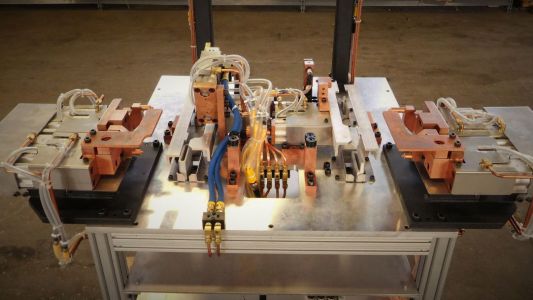

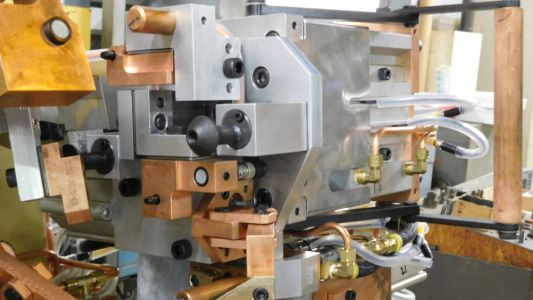

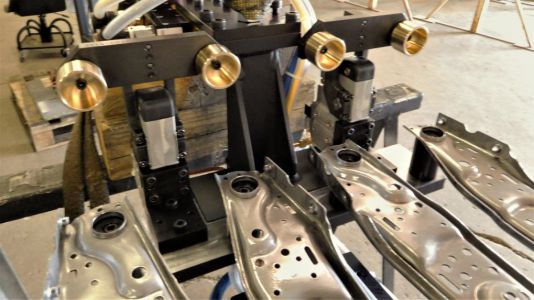

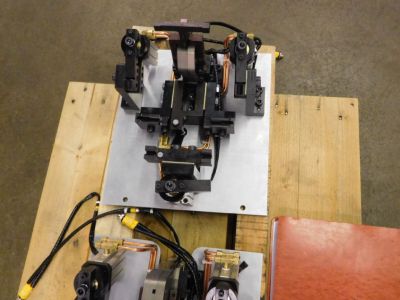

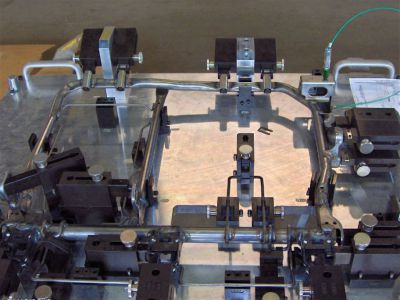

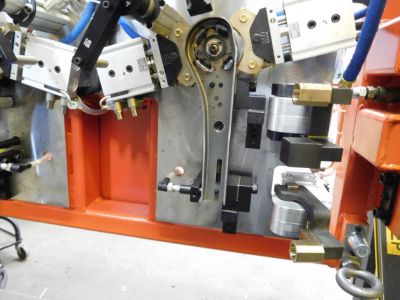

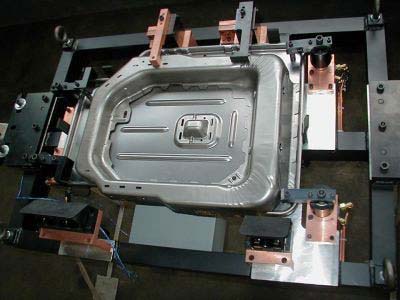

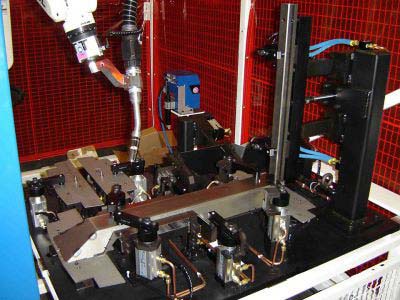

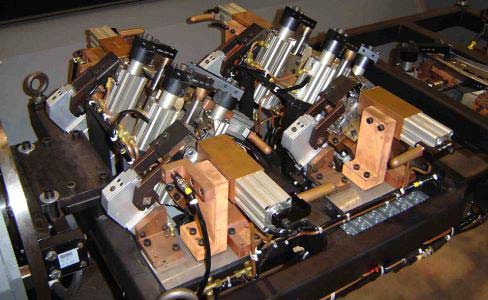

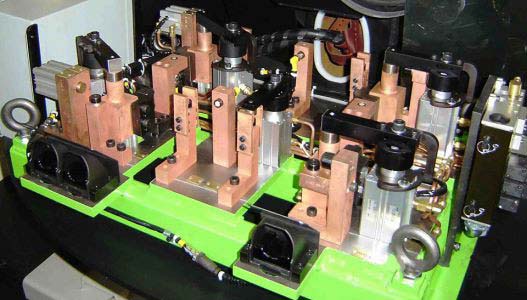

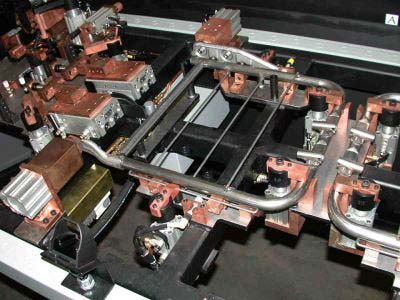

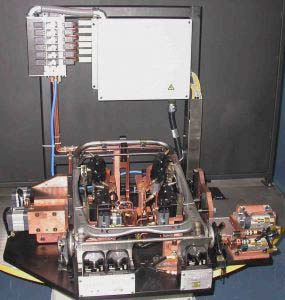

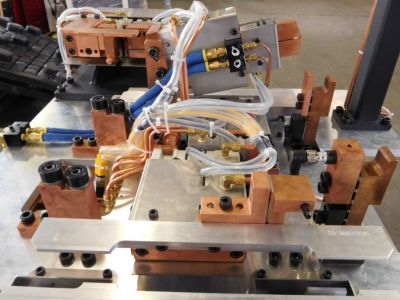

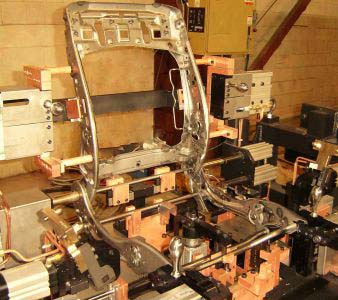

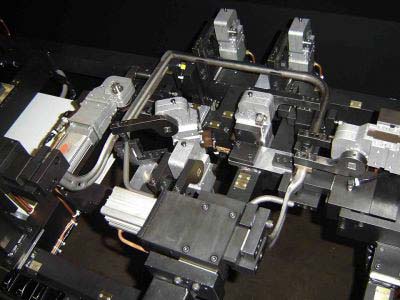

[Pictures of Stryver-built Weld Fixtures below]

A robust robotic arc welding fixture is a part-holding tool used to constrain components for welding in an automated system. To ensure the tool can withstand the demands of a mass production environment, typically the fixture needs to be custom built for the welding process. The weld tooling must be built to have adjustability for fixture tune-in to the proper dimensions. Sometimes welding fixtures are used on turnkey robotic cells with built-in rotating positioners, other times custom robotic cells are built to properly complete a welding process for the lowest cost and floorspace usage. A good systems integrator like Stryver will work with you to complete process analysis to determine the best, most cost-efficient welding solution for your parts.

As can be seen by the images below, fixturing a MIG or TIG welded assembly process for robotic welding presents many challenges for the welding jig. A robust, but simple and easy to alter design is critical to building a welding tool that is capable of welding parts correctly for a multi-year lifespan. The weld jig must hold the parts to the callouts on the welded assembly print and allow for all weld points to be accessed with a welding torch mounted to a robot.

Here are some of the key Critical to Quality characteristics Stryver considers when designing and building a weld fixture:

- Are all locating features able to be tuned into position in all three axes [XYZ]?

- Is each tooling detail made of a proper material to ensure the process can withstand the wear and tear of mass production, while also reducing weight where possible to minimize positioner wear as well as maintenance cost?

- Are wear components, like locating pins, made from off-the-shelf components our customers can easily go buy on their own if needed?

- How does the operator’s interaction with the weld tooling work throughout the entire cycle?

- Does the tooling ensure maximize torch access to welding points, and minimize the number of locations weld spatter can build up on a tool?

- Is each and every subcomponent of the welded assembly properly oriented and constrained in the welding fixture according to the datums & locating features on the print?

- Is the welding jig designed for quick heat dissipation? This is especially important for MIG welding jigs to minimize the possibility of part deformation

- Is proper weld spatter protection installed to ensure parts unloaded from the robotic welding fixture do not require post-welding modifications or repair?

Stryver has over 30 years of experience designing, building, integrating & installing automated welding jigs, fixtures & tooling. Our team has designed & built weld fixtures with fail-safe solutions built-in to minimize the possibility of issues including part deformation due to excess heat, improper fusion, voids, improper weld bead size, missing parts in the assembly, improper part fit-up, spatter build-up and weld porosity. Stryver’s welding fixtures, tooling & jigs are designed to be as compact as possible. Our fixtures and tooling jigs are designed to ensure a controlled welding environment, locking components into place inside the automated jig to minimize deflection with well-designed weld tooling clamping systems.

Stryver has the experience to make sure your tooling fully supports your robotic welding process, whether that process is GMAW / MIG, GTAW / TIG, or another Arc welding process. Stryver can also accommodate laser welding tooling & fixturing projects, which require even tighter part holding tolerances.

Let us put that experience to work for you to overcome these challenges on your project to achieve a successful outcome. Please review our examples below to get a better idea of our tooling designs and strategies.