Check Fixtures & Inspection Gauges

How do I determine if I need to confirm a dimension using a Check Fixture?

To determine if a dimensional callout on a drawing needs to be confirmed using a check fixture or inspection gauge, consider the effects to the production process if the part was made with the dimension in question out of tolerance.

- How severe would the effects be to the process if the part were out of tolerance?

- Given the manufacturing process and previous checks, how likely is this defect to occur?

- How difficult is the defect to detect or spot without using a check fixture or inspection gauge to confirm accuracy?

You may already be asking yourself these questions as part of a Failure Mode & Effect [FMEA] analysis. A check gauge is a great way to increase defect detection and ensure the process is held to the right dimensional tolerance.

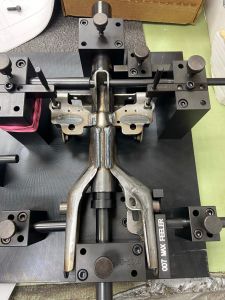

See below for examples of check fixtures we have built. Email This email address is being protected from spambots. You need JavaScript enabled to view it. with your project specifications.

Simple, manual testing fixtures & check fixtures are an easy way to ensure product quality with a minimal budget. Well-implemented check gauges can save your company time and money in the long run even in areas that have a higher tolerance or are less critical to downstream processes.

Case Study: Wire Harness Coupler Fastening Inspection Fixtures

In recent years, Stryver has built many wire harness coupler fastening fixtures. These fixtures are designed & machined to tight tolerances to hold the coupler ends, locate them within the fixture, set them together, verify the ends are properly fastened, and feed that data back to a database.

These coupler fastening fixtures are a vital device to ensure safety critical couplers are fastened properly on the assembly. Each coupler fastening fixture is custom designed and built for the individual coupler, and is precision ground to the correct dimensions. See above for examples of these fastening fixtures