Assembly Tooling & Fixturing

What is Assembly Tooling? What should I look for in an Assembly Tooling & Fixturing provider?

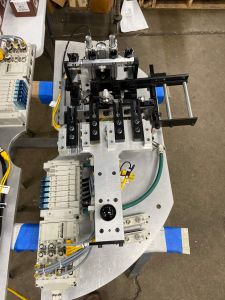

[Pictures of Stryver built Assembly Tools below]

An assembly tool is any fixturing or jig set used to assist with an assembly process. While the term is most commonly used for Aviation assembly processes, assembly tooling is needed in almost every type of manufacturing. Assembly tooling should be robust in construction to withstand hours of wear and tear a day for years at a time, and simple in design.

When sourcing Assembly Tooling, here is what we recommend you check to determine whether or not the potential supplier is a good fit for your project:

- Review past assembly tooling projects the tooling provider has completed. Has the potential supplier completed similar and/or more complex projects than the one you are looking to complete?

- Does the supplier build robust, precise equipment for assembly fixturing applications or other applications similar to yours?

- Is there a proper level of attention to detail in past assembly tooling builds or work to match the quality requirements you expect for your project?

- What is the supplier’s strategy for completing your assembly tooling process? Can the supplier share a rough concept and guide you through their tooling build plan?

- Will the tooling be allowed to adjust to accommodate variation in the process? Or does the tooling need to be designed to be fully rigid and not adjustable to ensure it is always calibrated to a certain level?

As a part of reviewing past work, another aspect to confirm is tooling durability for your project. For larger part holding applications, especially for aerospace assembly tooling where the parts to be fixtured can weigh thousands of pounds, the tooling needs to be robust enough to withstand this type of wear. Large, stress-relieved fabrications are often needed to hold the parts rigidly in place. For smaller applications, steel tooling plates or even aluminum plates may be sufficient to handle the process wear. Increased strength of materials will result in increased cost but using low-cost assembly fixturing can cause future issues with the assembly process.

When your assembly tooling provider creates a fixturing strategy for your process, their plan may require subassembly fixtures be used in conjunction with a final assembly fixture. The tooling provider should do whatever they can to minimize the amount of processing required to assemble your part, as well as minimize operator stress & strain. The fixture should also make accommodations for any hand tools that are required to be used for the process.

Tooling adjustability also needs to be considered by your assembly tooling provider. A rigid fixture with no adjustability built in will work poorly for assembly tooling processes because minor dimensional discrepancies within the tolerance callouts on the print cannot be accommodated. Adjustability should be built into every axis of every constraint to ensure proper part fit-up in the tooling for applications where the subcomponent part tolerances vary. Stryver can work with you to determine which areas need adjustability, and how much adjustability, to properly tool the assembly in the assembly jig.

Stryver has been building assembly fixtures, including aerospace assembly tooling, for over 25 years. Our company has completed a diverse portfolio of assembly tooling projects for industries including aerospace (assembly & testing equipment), automotive, consumer goods, defense/military, and medical device manufacturing. Please see below for examples of our past projects & work.