Robotic Systems Case Studies

Stryver Manufacturing is a full-service provider of robotic systems. We are a turn-key robotic systems integrator. Stryver has more than 25 years of experience integrating both pre-engineered and custom designed robot cells. We have installed and programmed hundreds of robot cells for welding, material handling, and other applications. Stryver offers full turnkey service design and build of robot cells, tooling, controls, and peripheral equipment.

One of the most critical components of any robotic system is the programming and integration behind it. Systems integration is the skeleton behind the motions that are designed specifically to allow the system to perform its tasks. You need the best programmers available to ensure these systems work correctly.

See below for examples of robotic systems Stryver has built over the years:

Custom Fully Automated Welding & Material Handling Cell

Stryver can handle every aspect of creating and implementing your new robotic system. We design, manufacture, and assemble your robotic system in our facility. Then we program and install your new system on your production floor after a successful runoff. Stryver strives to ensure your complete satisfaction throughout each and every step of the robotic cell building process.

The robotic welding cell shown above was custom designed and built by Stryver to weld a car seat frame together in one series of operations. This minimizes the number of robotic welding cells and operators required to complete this process, which in turn reduces capital expenditures on a program. Stryver integrated all of the robots shown above to complete this operation as well as built the tooling, grippers and WIP holding stands for welding and material handling processes.

Our robotic systems include solutions for gas metal arc welding and spot welding, tool change-out, material handling, and multi-robot systems among other applications. We offer full integration services to ensure your robotic system runs smoothly from day one and continues to run smoothly throughout its lifetime.

Our highly skilled programmers will ensure your new robotic system works properly and in step with the rest of your production processes. Stryver’s controls engineers and automation experts ensure the proper tooling and components are integrated into the robotic system. Our programmers are available to come to your facility and maintain the machine. From initial concept to final implementation, our team makes sure your robotic system will do the job correctly every time.

Service Welding Cell Built from Combining Production Welding Cells

This robotic welding cell was built from leftover components of multiple welding cells that were in production for the life cycle of a vehicle program. The components were well work and well-used but still fine to use for a lifetime of service production. The Stryver-built tooling in the cell was refurbished and reconfigured as needed to fit in the new service cell. Material handling robots were put in the cell to move the tooling from the appropriate rack to the positioner for welding and part loading.

Stryver implemented every aspect of this new robotic system, from refurbishment of well-used robotic & tooling components to systems integration and on-site installation. We strive to ensure our product works smoothly in your facility.

Stryver can help save you both time and money by redeploying your current robotic arms into new areas of production, with full integration services available to make your redeployment project easy and turn-key. Contact our team at This email address is being protected from spambots. You need JavaScript enabled to view it. and tell us your ideas. We can make them happen.

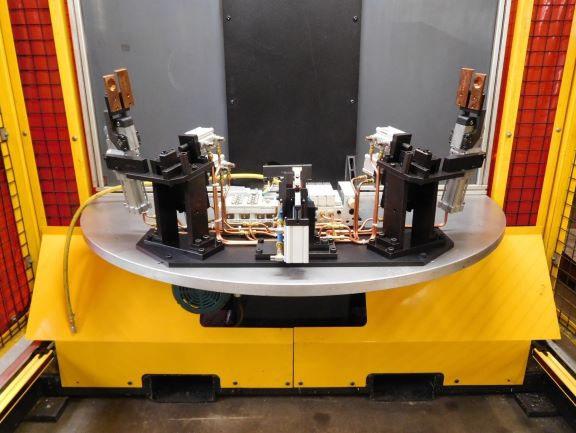

Reconditioned Fanuc Turntable Arc Welding Cell

Stryver designed and built the tooling shown above, reconditioned the turntable mounting plate and cell, reprogrammed the Fanuc welding cell, and completed part runoff validation on-site prior to shipment to the customer. The Fanuc cell was shipped to Stryver for reconditioning, then shipped back when completed and when the tooling was integrated onto the cell. Because Stryver has been doing robotic systems integration for over 25 years, we also have the expertise to handle systems of any age. If you have an old robot cell you are looking to redeploy, reach out to Stryver. We may be able to help you out for less than the cost of buying a new cell.